The flaws of a supercapacitor battery are as obvious as its strengths. Because of the fast discharge speed and low internal resistance of super batteries, if the planning is not good, there is a risk hidden in the "sudden explosion of energy". The supercapacitor can discharge very quickly, the output power can reach 24KW/Kg, a 50Kg supercapacitor battery, the output power is 1200KW, the car can fly by stepping on the switch.

The self-discharge rate is much faster than that of the battery, which is simply "unable to store electricity". Supercapacitors are always composed of capacitors. Capacitors are composed of an insulating dielectric sandwiched between two electrodes. In any case, there will be a flow of electrons between the two electrodes, which will reduce the amount of stored electricity. The super battery may die after a period of time after it is fully charged.

It is not resistant to high temperature. The operating temperature of the super battery is -40-70 °C, and it is resistant to high temperatures. If the temperature is too high, it will affect the operation and even damage the battery.

The important flaw is still the cost. Although countries around the world are accelerating the research and development of supercapacitors, it will take time for the idea of pulling capacitors to become widespread in civilian use.

The flaws of supercapacitor manufacturers can be overcome, and their skills are not yet mature. However, the development speed of Farad capacitors is very fast, and they can be used in civilian applications in the next few years. So why are they still difficult to find in automobiles?

This is a problem that many people in the industry are concerned about. To sum up, there are: the cost of production; the feasibility of industrialization of the preparation process, especially the environmental impact of the nitriding process; the energy density is far from the requirements of electric vehicles, how to deal with it.

capital issue

At present, chemical liquid-phase mechanical exfoliation method is widely used to prepare two-dimensional oxidized graphene micro-sheets with high cost. There are also problems that the use of chemical materials has a great impact on the environment, the need to restore graphene for a long time, and the conductivity decreases, and the two-dimensional micro-sheets are easy to stick. Formation, etc. A physical liquid-phase mechanical exfoliation method for preparing intrinsically restored three-dimensional graphene microplates has the advantages of low preparation cost and environmental friendliness, and invents conditions for the low-cost preparation of three-dimensional graphene electrode blocks by sol-gel method.

2. The impact of nitriding treatment on the environment

If the nitriding process of concentrated nitric acid commonly used in the laboratory is used in industrial production, it is indeed difficult to pass the EIA. In an industrial center project, a simple and low-cost technology to deal with nitrogen oxide pollution has been used.

The problem of energy density

Energy density is the "dead hole" of supercapacitors. In order to improve the energy density of supercapacitors, a lot of money and manpower have been invested in research at home and abroad. However, the research route at home and abroad is basically to study new electrode materials to improve the specific capacity of the electrode, or to study the composite electrode that produces a chemical reaction on the surface of the electrode. Density has yet to see a breakthrough.

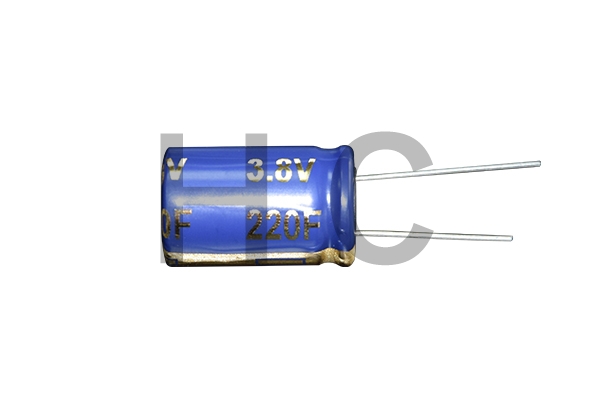

Generally, the specific capacity of the carbon electrode of the supercapacitor is less than 250 Farads/g. The known capacity material is ruthenium oxide, and its specific capacity is 900 Farads/g. However, the price of ruthenium oxide is too expensive to be used in industrial production.

As we all know, increasing the working voltage of the supercapacitor can improve the energy density of the capacitor, because the energy storage of the capacitor is proportional to the square of the working voltage of the capacitor.

The electrolyte for supercapacitors is mainly aqueous electrolyte. The operating voltage of aqueous electrolyte is generally not more than 1V, but compared with organic electrolyte, aqueous electrolyte has better conductivity (for example, H2SO4 solution can reach 0.8S/cm), lower price, and more environmentally friendly.

The research on improving the working voltage of supercapacitor modules, both at home and abroad, focuses on the research on electrolytes for new high-voltage operations. The use of organic electrolyte can improve the operating voltage of supercapacitors (2.3-2.7V), and ionic liquid electrolytes that can be used for 3V have also been reported, but due to the high cost of preparation, industrial production is also unbearable.

Is there any way to improve the working voltage of supercapacitors?

Supercapacitors are Faraday capacitors based on the electric double layer theory. The electric double layer theory was proposed by Helmhotz et al. in the 19th century. The Helmhotz model assumes that the electrostatic charge on the surface of the electrode adsorbs ions from the solution, and they are arranged in a row at a certain distance from the electrode on the solution side of the electrode/solution interface, forming a barrier with the same number of charges and the opposite sign of the remaining charges on the surface of the electrode. interface layer.